| Polyvinyl Chloride(PVC) Foam Boards |

|

|

PVC Foam board is a highly sturdy and lightweight foam board made for a variety of

indoor and outdoor applications. PVC stands for Polyvinyl Chloride, a popular synthetic

plastic polymer widely used in the market. PVC boards are also labeled as expanded,

moderately expanded, or cellular PVC and are some of the leading non-toxic

thermoplastic materials in the market.

Polyvinyl Chloride is made by the processing of polymerizing the monomer form of vinyl

chloride (abbr. VCM). This is done through a process called suspension polymerization.

As a result, a mixture is formed and expanded PVC is a highly strong, durable, and

long-lasting material due to the polymer and closed-cell structure as well as its chemical

composition.

There are two types of PVC material: rigid and flexible. Rigid PVC boards are ideal for

more solid and durable applications such as frames and piping, whereas flexible PVC is

ideal for insulation applications such as roofing and flooring.

Manufacturers and brands have developed their own PVC foam boards with varying

finishes and textures. Known PVC Foam boards in the market include Celtec, Veranda

(Cellular PVC), Versatex (Cellular PVC), and Sintra (Expanded, Moderately-Expanded

PVC).

|

| Applications/Usage

|

|

|

PVC foam boards are known to be versatile which allows them to be suitable for both

exterior and interior applications. Because of their lightweight, rigid, and highly resistant

properties, they are ideal for a number of different usages. ACPs are commonly used

(but not limited) for the following applications:

- As a substrate for painting and mounting

- POP displays, signage, signboards, store displays, and labelling

- Support for furniture and cabinets

- Wall and flooring insulation

- Wall panels for construction, offices building

- Can be used for decor and interior use

- Prop and art design and 3D display

- Replacement for wood

- Kitchen and home improvement

- Window displays and siding

- Cables, wiring, and piping

- Chemical and mechanical applications

|

PVC Boards

|

| Properties of PVC Foam Boards

|

|

|

Characteristics/Specifications

Expanded PVC has qualities and features that make them a top substrate choice in the

industry. PVC boards are known for (but not limited to) the following properties:

- PVC foam boards are known to be moisture and corrosion resistant which means

that it will not corrode or fade over the life of its application. PVC boards are also

waterproof. This makes the material highly resistant to water absorption.

- PVC foam boards are fire-retardant and have self extinguishing properties. Since

PVC boards are made of thermoplastic material, they are highly thermal and do

have a point in which they turn malleable and start to soften at 149 degrees

fahrenheit. PVC foam material is designed in which it cannot be flammable. In

addition, PVC has insulating properties.

- PVC is highly resistant to a number of elements and chemicals. In addition to

being fire and moisture resistant, PVC foam boards are manufactured to be

resistant to insects, mold, mildew, scratches, cracks, weather, noise, acid, and

most chemicals and toxins.

- PVC foam boards are easily processed and work well with a number of different

conventional, carpentry/wood, and commercial tools. In addition, PVC is easy to

work with and is malleable enough to be cut, bent, shaped, and is not easily

deformed due to lack of water absorption.

- PVC foam boards are an ideal alternative or replacement option to other

substrates and composites such as aluminum, wood, clay, metal (in certain

applications) and other foam boards. In addition, they are cost effective in

comparison to other composite materials because they are often and easily

manufactured.

- PVC is ideal material to print, emboss, laminate, and paint onto. Furthermore,

PVC boards do not require any additional priming, coating, or polishing.

|

| Thicknesses, Colours, Standard Sizes, and Weight

|

|

|

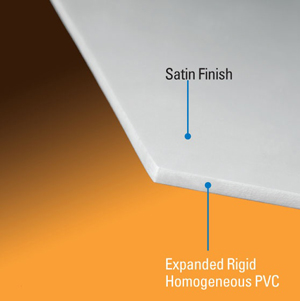

Colours & Finishes

PVC Foam boards are most commonly sold in black and white, but manufacturers now

offer a wide variety coloured PVC foam boards such as blue, yellow, red, range, green,

beige/tan, and grey/silver. In addition, PVC foam boards come in a range of textures

and finishes with the most common being a smooth, matte, and glossy finishes, or

ridge/wavy texture.

Thicknesses, Density, and Weights

Currently in the market, PVC boards come in a range of thicknesses with some of the

thinnest foam boards as thin as 1mm (approx. 0.04") to 45 mm (approx. 1.77"). Different

thicknesses and densities can work better than others for different applications. In terms

of density, PVCs can vary between 3 lbs/ft²

to 25 lbs/ft².

Custom & Standard Sizes

Depending on the manufacturer or brand, PVCs can be cut to almost any custom size

or may be supplied in standard/stock sizes (will vary based on manufacturer). PVCs can

be sold in custom sizes and can be custom cut as small as 4x4" squares. PVCs can be

sold in full panel sheets and can come in sizes as large as 4'x8' (48x96") and 6'x10'

(72x120"). Standard sizes in the market include 2x4' (24x48"), 4'x8' (48x96"), 5'x10'

(60x120").

|

Colored PVC Boards.

PVC boards come in a range of thicknesses.

|

| Key properties to consider before ordering PVC?

|

|

|

To order custom size board. Please use the "Price Calculator" on right panel for more details on pricing and available media types.

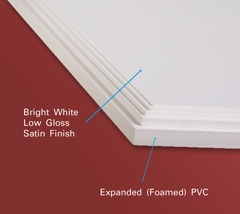

- We use and sells Sintra panels made by the leading brand manufacturer

3A Composites. They have been touted as the leading PVC board for more than

30 years. 3A composites manufacture a collection of Sintra boards with varying

finishes, thicknesses, and density for different applications. Sintra boards range

in thickness from 1mm-6mm and are usually made with a low gloss, satin finish.

- For most of our board mounting services (fine art mounting and dry mounting) as

well as our custom cut boards, we offer Sintra panels in black white and either

3mm or 6mm thicknesses. As mentioned above, Sintra PVC panels have self

extinguishing properties and hold a Class A fire rating for panels of 3mm or less.

- Sintra panels are known for everyday, medium-term application life however, 3A

composites does offer other products in the Sintra collection that range from

short to long-term application life. PVC panels are ideal for fabrication methods

such as: cold mounting, digital and screen printing, painting, cutting, and routing.

- We offer custom PVC panels that are the perfect mounting substrates for fine art

prints. You can order any custom fine art print on any of our coated,

photographic, or fine art papers and have it mounted onto Sintra to provide

structure and base to your custom print with the option for lamination. Sintra

boards provide a solid structure and strong base for propping artwork and

lamination.

- For dry mounting posters, prints, and photographs, we also provides PVC

as a substrate option. Dry mounting is done by heating Shellac tissue to adhere

the print onto the Sintra panel. This technique is used as an alternative to using

a wet adhesive to mount the poster or photograph.

- We also offers custom-cut PVC foam boards. We can custom cut PVC

panels for as small as 4"x4" square and up to 96"x48" which is a full 4x8' panel

sheet. We can guarantee a cutting accuracy of up to 1/8 of an inch. For usage, we

find that PVC panels are suitable for both interior and exterior uses and works

well for applications such as signage, window displays, exhibits, and large art

displays.

This article outlines the different backing boards available, and also provides some information

about their alternate use as mounting boards.

|

PVC with Satin Finish

|

|

If you have questions about any of our services or products, don't hesitate to contact us. Our knowledgeable staff is always happy to assist with answers, advice, or suggestions.

|

|

|

|

USA Giclee On Canvas, Fine Art Printing - Art Scanning & Reproductions - Handmade Oil Paintings - Custom Wood Panels, Metal Picture Framing - Block/Plaque Mountings, Large Format Dry Mounting & Lamination - Art Supplies: Stretcher Bars, Cradled Wood Panels and Artist Canvas - Collages On Canvas - Plexi/Acrylic Face Mounts - Block Acrylics, Fabric Printing, Dye Sublimation - Cityscape Skyline Prints, Resin, Photo Gifts and more...

|

|

© 2002-2025 - KeenART Media Ltd.

|

|

| |

|